OPTIMIZATION OF EQUIPMENT DESIGNS FOR VENEER PRODUCTION USING SOLIDWORKS SOFTWARE

DOI:

https://doi.org/10.36910/4293-52779-2025-17-01-06Keywords:

Veneer, optimization, hydraulic cylinder, SolidWorks.Abstract

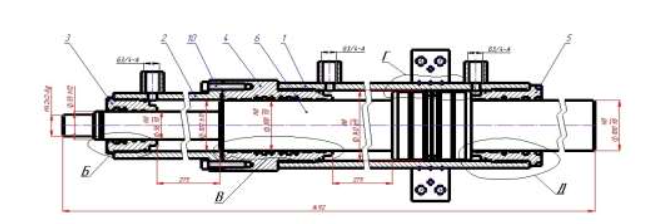

The article shows the introduction of computer technologies for optimizing the designs of equipment for the production of veneer. This will allow optimizing production work with the benefit of both attracting additional investments and maintaining human environmental well-being. A detailed study of the process of operation of an automatic oak veneer line, identifying the main shortcomings in its operation and methods for their elimination, as well as the main methods of optimizing equipment is relevant in modern production conditions. The paper shows the modernization of the hydraulic cylinder housing. The article shows the development of new or testing existing devices for suitability for use in the technology of manufacturing parts of appropriate complexity using modern SolidWorks software.

References

Hong, S.; Gu, Z.; Chen, L.; Zhu, P.; Lian, H. Synthesis of phenol formaldehyde (PF) resin for fast manufacturing laminated veneer lumber (LVL). Holzforschung 2018, 72. Рр. 745-752.

Ormarsson, S.; Sandberg, D. Numerical simulation of hot-pressed veneer products: Moulding, spring-back and distortion. Wood Mater. Sci. Eng. 2007, 2. Pp. 130-137.

Franke, T.; Herold, N.; Buchelt, B.; Pfriem, A. The potential of phenol-formaldehyde as plasticizing agent for moulding applications of wood veneer: Two-dimensional and three-dimensional moulding. Eur. J. Wood Wood Prod. 2018, 76. Pp. 1409-1416.

Forestry, Forest, Paper and Woodworking Industry 40:41-51.

Gupta, A.; Vaishya, R.; Khan, K. L. A.; Walia, R. S.; Singh, H., 2019: Multi-response optimization of hybrid filler composition for pultruded jute fiber reinforced polymer composite. Materials Research Express, 6 (11). Pp. 1-14. https://doi.org/10.1088/2053-1591/ab4945

A. Lobos and J. R. Vera. «Intertemporal stochastic sawmill planning: Modeling and managerial insights» Comput. Ind. Eng. 2016, vol. 95. Pp. 53-63.

C. G. Lundahl. «Optimized processes in sawmills». Licentiate thesis, Dept. Eng. Sci. Math., Luleå Univ. Technol., Division Wood Technol., Skellefteå Campus, Skellefteå, Sweden, 2007.