DRIVE POWER OF THE EQUIPMENT FOR THE MANUFACTURE OF CORRUGATED BOARD INVOLUTES OF DISTRIBUTION PACKAGING (JUSTIFICATION OF THE CALCULATION METHOD)

Abstract

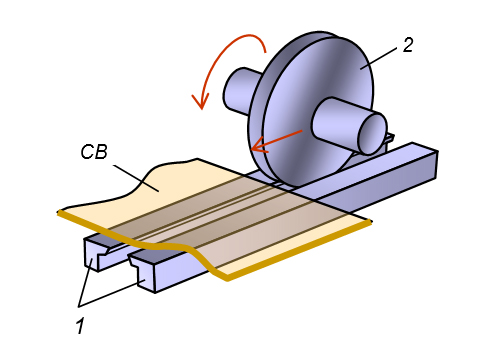

It has been established that the provision of modern industrial goods by the large-sized distributional packaging of corrugated board is related to the complexity of manufacture of involutes using die-cutting equipment. Large-sized involutes are obtained from several individual by gluing or binding with saddle stitching, that greatly complicates the technological process. A new technological process is proposed to eliminate the drawbacks and the unit for manufacturing large-sized involutes by means of scissor cutting with moving disk tools is developed, driven by a crank-sliding mechanism. In the article has been obtained mathematical expressions for invariants of kinematic parameters, relative instantaneous power, which spent by the unit for the manufacture of the large-sized involute of corrugated board.

References

Shreder, V.L. & Pilipenko, S.F. (2004). Cardboard packaging. Kyiv: IATs "Upakovka".

Emblem Anne & Emblem Henry. (2012). Packafing technology. Fundamentals, materials and processes. Woodhead Publishing.

Osyka, V.A. (2006). Packing materials and packaging: Textbook. Kyiv: National trade-economical university.

Rehey, I.I. (2011). Consumer cardboard packaging (materials, design, manufacturing equipment): tutorial. Lviv: Ukrainian academy of printing.

Rehey, I.I. (2009). Energy-efficient technology and tools for making cardboard packaging: a monograph. Lviv: Ukrainian academy of printing.

Rehey, I.I., & Koval, T.V. (2017, April). Development of a means for the manufacture of corrugated board packaging by scissor cutting method. International scientific-practical conference of publishing-printing problems. (pp. 66-70). Kyiv.

Poliudov, A.M. The mechanics of printing and packaging machines: Tutorial. Lviv: Ukrainian academy of printing.

Kuznetsov, V. O., Rehei, I. I. & Vlakh, V. V. (2017). Modification of a drive mechanism of a press plate in a die-cutting press. Printing and Publishing, 1(73), 56-62.

Palchevskyi, B.O., Krestianpol, O.A. & Bondarchuk, D.V. (2011). Calculation of the functional units of packaging machines: Textbook. Lutsk: LNTU.

Ezhov, S.M., Makarets, M.V., & Romanenko, O.V. (2008). Classical mechanics. Kyiv: Kyiv University.

Copyright (c) 2018 I. Регей, П.І. Бехен, С.В. Терницький, Т.В. Коваль

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.